“Fancy yarn makes each pair of jeans look different, and this has captured the fashion trend to the point where, today, ‘standard’ denim hardly exists. Fancy yarns mean denim is now a fashion item, rather than an everyday choice strictly for informal wear,” says Nitin Chokshi, Chief Manager, Quality Assurance (Head-Fibre/Yarn/Fabric-Testing Lab) within Arvind Ltd. The company has an yearly output of more than 40,000 tons and is a large producer of slub yarn for denim applications, supplying leading brands such as Levis, Wrangler, GAP, Diesel, H&M, Walmart, Marks & Spencer and J.C. Penney.

“Fancy yarn makes each pair of jeans look different, and this has captured the fashion trend to the point where, today, ‘standard’ denim hardly exists. Fancy yarns mean denim is now a fashion item, rather than an everyday choice strictly for informal wear,” says Nitin Chokshi, Chief Manager, Quality Assurance (Head-Fibre/Yarn/Fabric-Testing Lab) within Arvind Ltd. The company has an yearly output of more than 40,000 tons and is a large producer of slub yarn for denim applications, supplying leading brands such as Levis, Wrangler, GAP, Diesel, H&M, Walmart, Marks & Spencer and J.C. Penney.

Along the way, Arvind has built an outstanding expertise in the design, production and control of fancy yarns – a fact acknowledged by the number of other producers seeking Arvind’s help to improve their own denim manufacturing operations. Testing is vital, Chokshi says, to evaluate the relationship between cotton fiber parameters and the slub creation process for a continuous and reliable control of the yarn production process. The aim is to make apparently ‘random’ effects totally controllable and repeatable.

USTER’s Fancy Yarn Profile tool, as part of the USTER TESTER 5, has made this possible and providing tangible benefits on a daily basis: “The ability to evaluate fancy yarn characteristics, their relationship with the manufacturing process and their effect on ultimate fabric appearance has given us great confidence in controlling the yarn quality with the help of the Fancy Yarn Profile from USTER,” says Chokshi.

USTER’s Fancy Yarn Profile tool, as part of the USTER TESTER 5, has made this possible and providing tangible benefits on a daily basis: “The ability to evaluate fancy yarn characteristics, their relationship with the manufacturing process and their effect on ultimate fabric appearance has given us great confidence in controlling the yarn quality with the help of the Fancy Yarn Profile from USTER,” says Chokshi.

The Fancy Yarn Profile is based on precise sensor technology to measure and analyze slub yarns and features specially-tailored software to provide users with detailed reports on all important characteristics of the yarn. Aspects such as slub length and frequency, mass increase and decrease at critical points are accurately calculated to determine numeric values for yarn quality.

New standard for slub yarn measurement

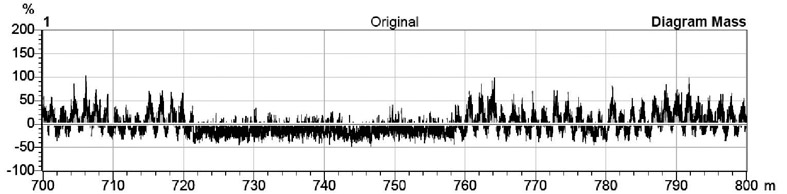

A novel feature of the latest software is the option to display a spectrogram with removed slubs, allowing the yarn to be checked for periodic faults. Mass diagrams can reveal potentially damaging long distances in the yarn where slubs are missing (see the accompanying diagram).

A series of diagrams can also display graphically the major characteristics of the slub yarn.

A series of diagrams can also display graphically the major characteristics of the slub yarn.

Data from scatter plot and histogram analyses can be combined into three-dimensional graphics showing mass increase, slub length and frequency. Overview information from the system can provide management with a daily quality control report, including fabric appearance and details of any loss of production efficiency in knitting or weaving.

Practical customer experience underlines the value of the Fancy Yarn Profile and how it can be adapted to solve various challenging issues. “It is most important to know all the parameters related to slub yarns, along with the matrix and all histograms. It helps to do sustainable R&D, to produce innovative fancy yarn effects. Most importantly, it offers the ability to deliver the required consistent fancy yarn quality – right first time through the instrument without producing trial fabric and waste,” Chokshi unveils.

More benefits result when the company applies data from the various reports to specific problems or defects, using each test parameter to help understand the effect of different cottons to produce a particular type of slub yarn. The most demanding tasks – mixing differing slub types and yarn counts and working with complex effect patterns – can only be accomplished by using the special software of the Fancy Yarn Profile. Knowing all this brings us to the conclusion that the USTER TESTER 5 is leading the denim revolution, thanks to the Fancy Yarn Profile tool.