UCMTF, the French Textile Machinery Manufacturers Association is an internationally active organization. Mr. Bruno Ameline, the President, and Ms. Evelyne Cholet, the Secretary General, share their thoughts on the global textile industry and the role played by French machinery manufacturers.

UCMTF, the French Textile Machinery Manufacturers Association is an internationally active organization. Mr. Bruno Ameline, the President, and Ms. Evelyne Cholet, the Secretary General, share their thoughts on the global textile industry and the role played by French machinery manufacturers.

Question: In which sectors is the French machinery particularly strong?

Answer: I would like to mention the illustrious name of Jacquard, the French inventor of the most sophisticated weaving technology. The French machinery manufacturers have played a particularly important role in the historical development of the textile industry and will continue to do so. That’s our technical tradition.

For the long fibre spinning industry, we develop new techniques to improve dramatically the quality standards, the operating and maintenance costs, and online quality controls. The innovating range includes the design of complete lines.

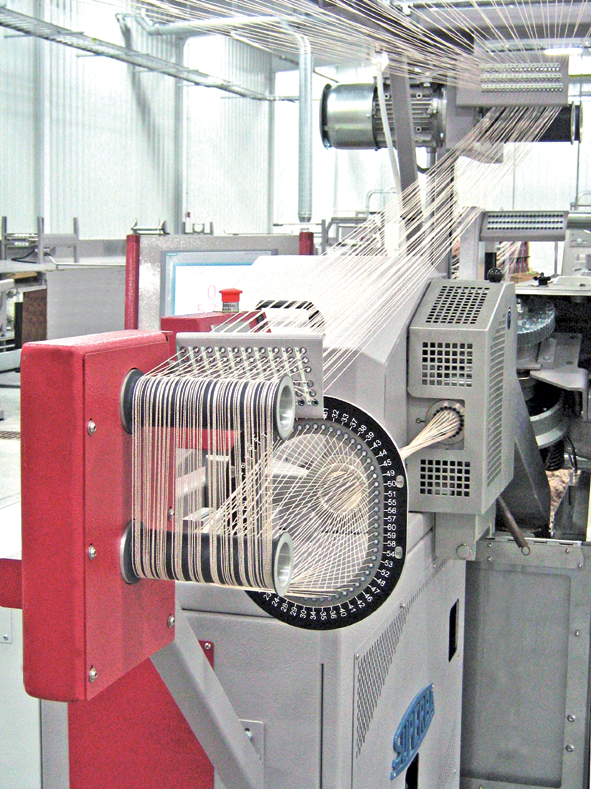

For the twisting and texturing of yarns, we offer our customers the opportunity to develop high-tech yarns for traditional and technical applications as glass fiber or tyre cord. Heat setting processes evolve thanks to many breakthroughs and offer new functionalities to yarns, for the carpet industry particularly.

Jacquard machines and dobbies developments make feasible spectac ular increases in the speed of production processes, together with higher quality and more reliability.

ular increases in the speed of production processes, together with higher quality and more reliability.

Dyeing consistency improves together with energy and water savings which, without our technical developments, would have been thought out of scope a few years ago.

In new sectors of the textile industry like the nonwoven processes which are growing fast for such applications as hygiene products (diapers, wipes), geotextiles, filtration, etc., the French machinery is also at the pinpoint of innovation.

Recycling the textile materials at the end of their life cycle and transform them into new products, being environmentally friendly, is also an issue on which the French machinery manufacturers are among world leaders.

In a word, the French machinery manufacturers offer the best and most reliable, productive and energy-efficient processes both for traditional applications and for new sectors in the industry.

Q: Is there a specific commercial strategy?

A: We have both commercial and technical traditions and French machinery manufacturers build their commercial strategies on these traditions. Blending tradition and innovation is a winning strategy. French machinery manufacturers are less and less offering standard machines but, more and more, tailor-made solutions designed with their customers and partners to enable these customers to introduce new products with high added value and compete successfully in their own national market and in the open world.

A: We have both commercial and technical traditions and French machinery manufacturers build their commercial strategies on these traditions. Blending tradition and innovation is a winning strategy. French machinery manufacturers are less and less offering standard machines but, more and more, tailor-made solutions designed with their customers and partners to enable these customers to introduce new products with high added value and compete successfully in their own national market and in the open world.

Personal contacts are necessary to achieve this goal: permanent agents in each country, numerous visits by experts from France, participation in events or shows.

It would be too long a list to mention all the textile shows our companies will attend in 2012. To name just a few: Megatex and Igatex, both in Lahore, ITM in Istanbul, India ITME in Mumbai, Techtextil (Russia, America, China), the JEC composite shows in France, etc.

After having organized seminars in Turkey, Syria, India and Brazil recently, UCMTF organized a conference in Bandung (Indonesia) in early 2012 with the support of Ubifrance, France’s agency for international development, of API, the Association of Indonesian textile, the Indonesian Ministry of Industry, the textile center of Bandung and HSBC Bank. As we want to be partners for the local companies, we were particularly pleased that textile companies attended not only from Bandung but also from Jogjakarta, Samarang, Solo and Surabaya. You can see that on each national market we go as deep as possible into the roots of the local textile industry.

After having organized seminars in Turkey, Syria, India and Brazil recently, UCMTF organized a conference in Bandung (Indonesia) in early 2012 with the support of Ubifrance, France’s agency for international development, of API, the Association of Indonesian textile, the Indonesian Ministry of Industry, the textile center of Bandung and HSBC Bank. As we want to be partners for the local companies, we were particularly pleased that textile companies attended not only from Bandung but also from Jogjakarta, Samarang, Solo and Surabaya. You can see that on each national market we go as deep as possible into the roots of the local textile industry.

Q: Which services can you offer to so many customers in so remote places?

A: Each company has organized the best service to help its customers get the best productivity from their equipment with online service, quick delivery of spare parts, etc. It is a key request that French manufacturers consider as an essential part of any deal.

We are SMEs, and organizing such a service was a real challenge. We have done it country by country, with our own experts and with local representatives. Being as close as possible to our customers is part of our genetics, of our DNA.

I would like to add, concerning spare parts, that, as an organization, UCMTF works to increase awareness of our customers on risks associated with not using original spare parts and to help our members organize the best logistics to deliver them.

Q: Can you tell us about the current state of your industry?

A: Our activity has rebounded since 2010 but has not fully recovered the best levels it achieved before the financial and economic crisis which hit mostly North American and European markets. ITMA 2011 in Barcelona was a very active and professional fair. Textile producers came with very interesting projects and many have turned into orders but quite a number have not yet. I believe this is mainly due to the increasing financing difficulties. Textile producers are often family run companies looking for long-term growth and not for short-term profits. They want to open new markets or develop the existing ones, they want to optimize their productions processes and have very well-planned investments projects.

On the other hand they can be constrained by the economic slowdown in Europe and, more recently, even in China. The US now seems to be on a growth path again which may contribute to boost the global economy. The other obstacle is the credit crunch, we European have been dealing with it for quite a while and therefore have found creative solutions.

Altogether most of our activity is now secured for 2012, but visibility is still limited into 2013. For the long term, we remain quite optimistic as we trust our strategy is right; our industry will continue to innovate and its structure will evolve. Reorganization in the machinery industry has been quite active recently all over the world, in France too.

Q: Can you tell us how UCMTF participates in the long-term strategy of your members?

A: Concerning R and D, UCMTF is active promoting the energy savings that the textile production processes can favour. Concerning our marketing strategy, I already explained our collective approach of some strategic markets. As an association we promote our members’ participation in the major textile shows and work closely with the textile media.

Another important objective of our association is to promote our industry among engineering and management schools. For that purpose we organize a Forum and finance an UCMTF prize through the prestigious “Challenge ITECH”.

It is important to remind that France is the sixth textile machinery exporter worldwide. Together the 35 manufacturers’ annual exports exceed 1 billion Euros ($1.3 billion). UCMTF, a member of CEMATEX, owner of the ITMA brand, has its website www.ucmtf.com