Lenzing, the world’s leading manufacturer of innovative cellulose fibers, presented the botanic towel featuring the Edelweiss effect at Heimtextil in Frankfurt held during January 11-14. Thanks to the natural origin of the fiber, Lenzing Modal is made from beech wood, and the botanic feeling can be incorporated into remarkable terry goods. Beech wood proliferates by rejuvenation. So no reforestation or plantations are necessary. More than half of the wood used at Lenzing comes from Austria and the remainder from the neighboring countries.

Lenzing, the world’s leading manufacturer of innovative cellulose fibers, presented the botanic towel featuring the Edelweiss effect at Heimtextil in Frankfurt held during January 11-14. Thanks to the natural origin of the fiber, Lenzing Modal is made from beech wood, and the botanic feeling can be incorporated into remarkable terry goods. Beech wood proliferates by rejuvenation. So no reforestation or plantations are necessary. More than half of the wood used at Lenzing comes from Austria and the remainder from the neighboring countries.

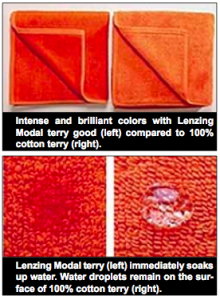

The botanic origin of Lenzing Modal provides critical sustainability benefits for terry goods, benefits that are becoming increasingly important. However, it is not only the fiber’s eco-friendliness that makes it so compelling. Its performance properties such as color brilliance, absorbency and softness make terry goods of Lenzing Modal particularly appealing to consumers. In fact, 89 per cent of consumers in a recent survey stated that towels with Lenzing Modal stay softer than 100 per cent cotton towels even after repeated washing. Plus, colors are richer and more intense with Lenzing Modal.

Gradual fading or graying is no longer an issue with Lenzing Modal terry goods. Finally, these towels deliver a higher absorption rate than 100 per cent cotton towels, thanks to the fiber’s unique structure.

With Edelweiss, Lenzing is setting new technological and environmental standards for the entire cellulose fiber industry. Lenzing’s innovative Modal production process involves oxygen-based chemistry. It is more environmentally friendly than conventional production procedures.

Thus Lenzing Modal Edelweiss is the only Modal fiber to satisfy the highest environmental standards. Environmental benefits such as the replenishable and natural raw material, CO2-neutrality and the highest production yield make the new Lenzing Modal Edelweiss the eco-fiber of choice.

Lenzing Modal Edelweiss is produced differently from the conventional Lenzing Modal, but the fibers’ main properties such as softness and color brilliance are the same. The fibers process identically at all points in the textile chain.

Susanne Jary, Lenzing’s head of marketing for home textiles, explains how unique Edelweiss is. ìThe fiber plant in Lenzing Austria is the only one in the world which is fully integrated and has all production steps, from the pulp to the fiber, perfectly under control. Throughout the entire process, attention is paid to environmental protectionî.

Susanne Jary, Lenzing’s head of marketing for home textiles, explains how unique Edelweiss is. ìThe fiber plant in Lenzing Austria is the only one in the world which is fully integrated and has all production steps, from the pulp to the fiber, perfectly under control. Throughout the entire process, attention is paid to environmental protectionî.

Lenzing is a pioneer in the field of wood-organic refineries. The integrated, CO2-neutral process at the company site, in combination with other innovative processes, results in excess energy generation and the production of high quality chemicals from the wood. The pulp factory serves as a net supplier of power for the entire Lenzing site. These special processes were developed by Lenzing and are not commercially available.