Frequency-controlled and motor-driven, the anti-patterning control (APC) upgrade package for rotor spinning machines optimizes package build. The conversion kit is available for R 1, R 20 and R 40 (version 1 to 3) rotor spinning machines.

Frequency-controlled and motor-driven, the anti-patterning control (APC) upgrade package for rotor spinning machines optimizes package build. The conversion kit is available for R 1, R 20 and R 40 (version 1 to 3) rotor spinning machines.

Higher draw-off speeds in weaving and knitting make optimal package build increasingly important. Preventing pattern winding results in improved take-off behavior in downstream processing. Electronic anti-patterning such as that in use since the R 40 rotor spinning machine (version 4) has demonstrated its outstanding qualities in the field. Customers with R 1, R 20 and R 40 (version 1 to 3) rotor spinning machines can now also benefit from this innovation.

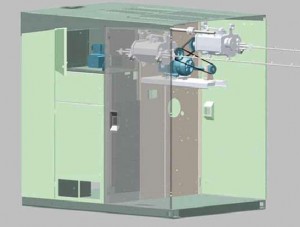

The APC upgrade package has been developed for this purpose. The mechanical regulating wheel has been replaced here by a frequency-controlled, motor-powered anti-patterning.

In addition to the mechanical regulating wheel, the other parts susceptible to wear such as the special belt and the mechanical anti-patterning gear are also dispensed with in the new system. This reduces maintenance effort. The new system completely eliminates the cost of purchasing or replacing these mechanical parts.

Perfect package build is the result of optimal anti-patterning. This prevents first-order pattern winding (1:1 pattern winding) and uncontrolled package winding. A separate motor with an electronic random-check generator ensures optimal anti-patterning. The rotation speed of the traversing gear can be finely controlled. The independent, motor-powered drive of the traversing gear also reduces the load on the winding cylinder drive.

The rotation speed of the winding cylinder shaft is picked up by a motion sensor (initiator). The necessary rotation speed for the motor is calculated by the controller and transmitted to the inverter. The motor speed at power take-off is then checked and regulated. Thus processed, these measured signals permit very accurate regulation and thus faultless anti-patterning.

Two optional settings on the controller enable anti-patterning intensity to be variably adjusted, usefully and very easily. These two adjustment options depend on the delivery speed and the yarn properties (pronounced snarling tendency, high elongation or other unusual properties). The angle of intersection is still adjusted by means of change gears.

Technical and technological developments in rotor spinning continue to make progress. The APC upgrade package also modernizes older machines to the latest state of the art. Improved package quality without ribbon formation, reduced maintenance effort and longer service life of the pattern breaker make investment in this upgrade package a worthwhile proposition.