Special thrust on better prices for cotton growers

The Chief Minister, Mr. Narendra Modi, has announced a new Gujarat Vastraniti (Gujarat Textile Policy) 2012 to establish the State’s unique identity at the national and international levels, in recognition of its enviable march to another ‘White Revolution in Cotton’, thanks to the untiring efforts of its cotton growers.

The Chief Minister, Mr. Narendra Modi, has announced a new Gujarat Vastraniti (Gujarat Textile Policy) 2012 to establish the State’s unique identity at the national and international levels, in recognition of its enviable march to another ‘White Revolution in Cotton’, thanks to the untiring efforts of its cotton growers.

The new textile policy is expected to attract investment of over Rs. 20,000 crores, creating new employment opportunities for over 25 lakh people, 50 per cent of them being rural women, during the next five-year period. This will also increase the State’s revenue and growth rate along with that of the textile industry.

Gujarat has recorded an exponential growth in raw cotton production during the last 10 years. It is up from 23 lakh bales to 1.23 crore bales over the period, particularly due to farmers adopting the State Government-sponsored scientific methods of farming and BT cotton. Gujarat cotton is in demand in China, Europe and other important markets.

The objective of the new policy is in keeping with the interest of the cotton growing farmers, better price realization in national and international markets, and value addition in the entire chain. It is also to protect the cotton growers of Gujarat from the UPA Government’s anti-farmer and anti-export policies. The Centre bans export on raw cotton exactly when the international prices are the highest. It cost dearly the Gujarat farmers with a loss of Rs. 14,000 crores in the outgoing season.

The objective of the new policy is in keeping with the interest of the cotton growing farmers, better price realization in national and international markets, and value addition in the entire chain. It is also to protect the cotton growers of Gujarat from the UPA Government’s anti-farmer and anti-export policies. The Centre bans export on raw cotton exactly when the international prices are the highest. It cost dearly the Gujarat farmers with a loss of Rs. 14,000 crores in the outgoing season.

The new policy envisages an integrated approach to strengthen the value chain “Farm to Fibre to Fabric to Fashion to Foreign”, enhancing sustainable growth of farmers and the industry. It has many more unique, progressive and futuristic policy supports, financial and other supports for different schemes in different sectors, as follows:

The new policy is to enhance the growth of cotton farmers and ginners by way of better price realization and to enable them to withstand uncertainties due to price fluctuations. The focus is on new cotton spinning activities to strengthen the value chain.

The new policy is to enhance the growth of cotton farmers and ginners by way of better price realization and to enable them to withstand uncertainties due to price fluctuations. The focus is on new cotton spinning activities to strengthen the value chain.

– Interest subsidy of five per cent, without ceiling for five years on new plant & machinery for ginning & processing

– Interest subsidy of seven per cent on new plant and machinery for cotton spinning, as well as for second-hand imported cotton spinning machinery with certain conditions, without ceiling for five years.

– Power tariff concession on new investment for cotton spinning at the rate of a rupee per unit for the five-year period.

– Minimum 150-acre land, stamp duty exemption to developers and units, and assistance up to 50 per cent with maximum ceiling of Rs. 30 crores for common infrastructure for cotton spinning park with or without weaving.

– Minimum 150-acre land, stamp duty exemption to developers and units, and assistance up to 50 per cent with maximum ceiling of Rs. 30 crores for common infrastructure for cotton spinning park with or without weaving.

– Stamp duty exemption to developers and units in parks, and assistance up to 50 per cent with maximum ceiling of Rs. 10 crores for common infrastructure in parks and other textile activities.

– Refund of value-added tax (VAT) paid by cotton-based units, like ginning, spinning and weaving, on purchase of cotton / cotton yarn and remission of tax collected on cotton yarn (applicable to the extent of investment in plant & machineries).

Modern weaving, knitting and machine carpeting activities. Here the move is to strengthen the value chain, development of cotton base weaving and knitting activities to boost the growth of cotton spinning in the State. Technology upgradation of the existing synthetic and filament powerloom weaving industry will also be undertaken to fulfill the requirement of the international market of the art-silk industry. Gujarat is a leading producer of carpet wool. Encouragement is, therefore, given for establishing modern carpet manufacturing activities in the State.

– Interest subsidy of five per cent on new plant and machinery, without ceiling, for weaving, knitting, machine carpeting and other textile-related activities, as also on second-hand imported weaving (powerloom) with certain conditions, for five years.

– Interest subsidy of five per cent on new plant and machinery, without ceiling, for weaving, knitting, machine carpeting and other textile-related activities, as also on second-hand imported weaving (powerloom) with certain conditions, for five years.

– Power tariff concession of a rupee per unit for the period for weaving.

Dyeing & processing

It is to have a substantial value addition through technological upgradation and modernization in the dyeing and processing sector. Encouragement is given to establish energy-efficient and environment-friendly modern dyeing and processing units.

– Interest subsidy of five per cent on new plant and machinery, without ceiling for a period of five years, in dyeing and processing.

– Assistance up to 50 per cent for audit report amounting to a maximum of Rs. 50,000, assistance up to 20 per cent of the cost of equipment, subject to maximum Rs. 20 lakhs, eligible once in two years during the operation period of the scheme, as support for energy and water conservation and environmental compliance, for the processing sector and the entire value chain.

Garments & made-ups

Garment and made-ups are the driving force for overall growth of the textile value chain. It is also highly labour intensive mainly for rural women. Encouragement is, therefore, given for setting up of new and modern garment and made-up units even in interior parts of the State.

– Interest subsidy of seven per cent on new plants and machinery, without ceiling for a period of five years, for garments and made-ups.

– Refund of VAT paid by the unit on purchase of raw material and remission of tax collected on readymade garments, as VAT concession (applicable to the extent of investment in plant & machineries).

Technical textiles

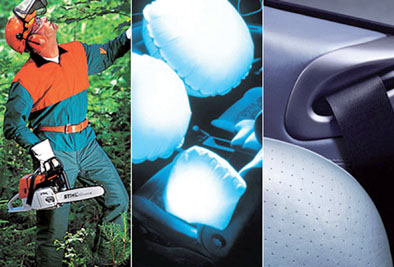

Looking to the enormous industrial growth in the State and potential for technical textiles worldwide with applications in industries like agriculture, medicals, automobile, defence, etc., development of this segment will lead to high value addition on the textile value chain and better realization and sustainability.

– Interest subsidy of six per cent on new plant and machinery, besides second-hand imported machinery, with certain conditions allowed, without ceiling for the five-year period.

Apparel training institutes/centers

This is with an objective to create skilled manpower. For rural women employment, an approach is made to establish the required skill development.

For establishing apparel training institutes, assistance up to 85 per cent is given, subject to a maximum Rs. 3 crores, excluding land cost.

– Need-based support towards equipment for upgradation of facilities in ITIs.

– Assistance up to 50 per cent, subject to a maximum Rs. 20 lakhs, for training centres.

– Reimbursement of tuition fees to trainees as assistance @ 50 per cent, up to Rs. 7,000 per trainee per course

– Reimbursement of the training cost with a maximum of Rs. 7,000 per trainer per week, as assistance to training to trainers.

For training for weaving skill development, stipend is offered to trainees @ Rs. 2,500 per month for three months, and allowance to weavers @ Rs. 200/day and to jobbers @ Rs. 300/day. Assistance for advanced training to powerloom owner/jobber and worker, as also training for skill development in the powerloom / weaving sector.

Technology acquisition & upgradation is intended to withstand competitive environment both nationally and internationally for adopting modern technology. This approach has been adopted to encourage units for acquiring technology from abroad.

Financial assistance up to 50 per cent, with maximum of Rs. 25 lakhs per process/product is given once during the operating period of the scheme. It is also available for manufacturing textile machinery for the technology acquisition for the entire value chain.