By K. Gopalakrishnan

Erhardt+Leimer, a German specialist for system solutions and automation technology on running webs and belts, ranks among the worldwide leading suppliers of control, guiding and inspection systems for the textile, paper, corrugating, film, tyre, rubber, non-woven, and printing industries. Its broad product range comprises customized solutions for web control, web guiding and spreading, web tension measurement and control, cutting technology, measuring and inspection technology as well as print image monitoring.

Erhardt+Leimer, a German specialist for system solutions and automation technology on running webs and belts, ranks among the worldwide leading suppliers of control, guiding and inspection systems for the textile, paper, corrugating, film, tyre, rubber, non-woven, and printing industries. Its broad product range comprises customized solutions for web control, web guiding and spreading, web tension measurement and control, cutting technology, measuring and inspection technology as well as print image monitoring.

The Indian entity, Erhardt + Leimer (India) Pvt. Ltd., is a joint venture between Pramol Traders Holding (P) Ltd. and Erhardt+Leimer GmbH. Established in 1978, the company manufactures and markets sophisticated web guiding systems and web tension monitoring systems for textile, paper, film, foil, tyre and corrugating industries.

Mr. Seshadri Rajaram, the first employee of the company way back in 1978, is currently the CEO of the Indian entity. He says: “We started with 10 people and a turnover of Rs. 32 lakhs in the first year, and this year our turnover would be Rs. 60 crores with 260 people. We would like to double this turnover in the next 3 to 4 years”.

Till 2006 the company operated out of rented premises, and in 2006, E+L established its own state-of-the-art manufacturing facility in Ahmedabad.

Till 2006 the company operated out of rented premises, and in 2006, E+L established its own state-of-the-art manufacturing facility in Ahmedabad.

The textile industry is an important vertical for E+L. It contributes nearly 25-30 per cent of the total turnover, next to printing and packaging. Textile and the printing and packaging industry together account for nearly 75-80 per cent of the total business for E+L.

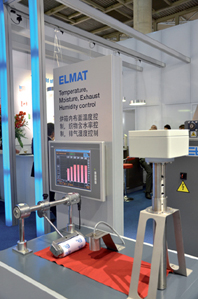

E+L offers an extensive range of products for the textile industry, including cloth guiders, uncurlers, stenter infeed devices, cloth centering and spreading devices, cutting devices, rope opening plants, weft straightners, moisture control and exhaust humidity control systems. Most of the products are manufactured in India. For some components like cloth guiders and uncurlers, India is the manufacturing hub for E+L catering to the requirement across all global markets.

“Of the products manufactured, in the stenter infeed device and cloth guiders we hold more than 70% market share in India”.

E+L is a preferred vendor to all major Indian and global OEMs of stenter, processing and printing machines. The company’s long list of clients in India includes Inspiron, Harish Textiles, Lucy, Stenmech, Swastik, Dhall, Yamuna, Hi-tech, Kusters Calico, Menzel, Texfab, Confident Engineering, Erbatech, Stovec, Ronson, Prashant Group and Jupiter Comtex. The OEM business contributes 55-65 per cent of the company’s total sales from the textile industry. Specifically for the stenter infeed device and cloth guiders, E+L is the clear market leader with more than 70 per cent market share.

E+L is a preferred vendor to all major Indian and global OEMs of stenter, processing and printing machines. The company’s long list of clients in India includes Inspiron, Harish Textiles, Lucy, Stenmech, Swastik, Dhall, Yamuna, Hi-tech, Kusters Calico, Menzel, Texfab, Confident Engineering, Erbatech, Stovec, Ronson, Prashant Group and Jupiter Comtex. The OEM business contributes 55-65 per cent of the company’s total sales from the textile industry. Specifically for the stenter infeed device and cloth guiders, E+L is the clear market leader with more than 70 per cent market share.

Mr. Rajaram says: “We are the first choice for most of our customers. The stenter infeed device for example is the heart of the machine, and if that doesn’t work it has to be attended on site within a few hours. It is so critical, and hence the reliability of our products, coupled with excellent after-sales service, has made our products the preferred choice for most customers”. The company has established an extensive network of offices, agents and service engineers in all major markets across India.

At India ITME, E+L is planning to launch two main products, the new compact stenter infeed device KR 60 and the new Web cutting system ELCUT BTA 80 for trimming of knit fabric at exit of stenter. In the last couple of years, the company has been selling a good number of rope opening plants.

“We feel the market for wet slitting plants is growing, hence we are going to showcase a complete stainless steel wet slitting plant for opening and slitting of tubular knit fabrics. We will also showcase our weft straighteners and stenter controls which will consist of residual moisture controller, exhaust humidity controller and fabric temperature monitor”, Mr. Rajaram adds.