76

|

The Textile Magazine

SEPTEMBER 2011

significant energy savings for cus-

tomers”.

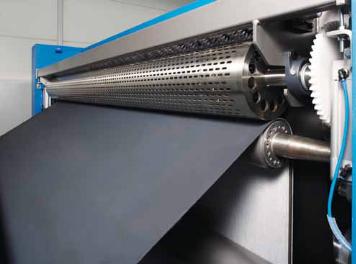

Habasit offers end-to-end solu-

tions, with a range of specialized

belts and tapes for textile plants.

Habasit tangential belts are de-

signed to cut power consumption

to the minimum. Its polyester power

transmission belts, such as the TC-

20/25EF and the new TC Quantum

leap types (TCxxQ), deliver high

performance yarn processing while

consuming 4-6 per cent less power

compared with the conventional

polyamide products.

Habasit’s W-8 polyester spindle

tape has a lower bending resistance

which saves up to 8 per cent of ring

frame motor energy consumption.

This is expected to result in savings

of an estimated 15 kWh a year per

spindle. Conversion campaigns at

over 2,000 sites have demonstrat-

ed that conversion from V-belts to

Habasit’s polyester-based TC-flat

belts results in energy consumption

reductions of 4-6 per cent.

Mr. Subramaniam says: “Our

technologies are very relevant to

the Indian market as the focus is

more on energy saving and effi-

ciency. All our products are devel-

oped keeping in mind the end-user,

particularly in markets like India”.

Habasit is also catering to the re-

quirements of non-textile industries.

The company is one of the largest

suppliers of printing blankets for

the printing industry. Almost 80-90

per cent of the TPU printing blanket

market is covered by Habasit.

India has its important role in

Habasit’s global business, contrib-

uting to nearly 10 per cent of the

ITMA 2011

[preview]