The Textile Magazine

SEPTEMBER 2011

|

125

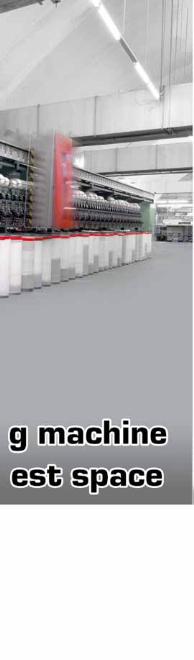

The new spinning unit of the J

20 ensures higher yarn strength

and fewer imperfections. The im-

proved yarn quality also results

in a lower number of quality cuts

and natural ends down. Together

with the reliable robots of the J

20, far greater production ef-

ficiency is achieved, resulting in

high yarn production.

Due to the increased spinning

stability with fewer quality cuts, it

was possible to lengthen the J 20

by one section to a total of 120

highly productive spinning po-

sitions. The J 20 is therefore the

longest air-spinning machine

worldwide. Four robots, two on

each side, ensure maximum pro-

duction efficiency. The option of

separate sides makes the machine

even more flexible, allowing two

different yarn qualities to be pro-

duced simultaneously.

A further improvement realized

with the J 20 is the optimized ma-

chine construction. The centrally-

driven ventilators, the entire elec-

tric and electronic systems as well

as the supply and disposal con-

nections are integrated in the drive

frame. Separate filter chambers

process the waste from the spin-

ning positions, as also the waste

from the robots.

The bobbin delivery on the drive

frame has been lowered to a

height of 1.45 metres. This ena-

bles the bobbin conveyor belt to be

optimally controlled by the opera-

tor and the bobbins conveniently

removed and placed on pallets.

The end section only consists of

the service area for the robot at the

rear and the free-standing tube

feeder with an extended capacity

of 350 empty tubes. The two sepa-

rate tube chains, which allow dif-

ferent color tubes to be fed to the

left and right machine sides, are

a new feature of the tube feeder.

This prevents tubes being mixed

up when two yarn qualities are be-

ing simultaneously produced.

w

new products