Basic HTML Version

104

|

The Textile Magazine

MARCH 2012

Improved anti-patterning control

package for rotor spinning units

technology

as the special belt and the mechani-

cal anti-patterning gear are also dis-

pensed with in the new system. This

reduces maintenance effort. The

new system completely eliminates

the cost of purchasing or replacing

these mechanical parts.

Perfect package build is the re-

sult of optimal anti-patterning. This

prevents first-order pattern winding

(1:1 pattern winding) and uncon-

trolled package winding. A separate

motor with an electronic random-

check generator ensures optimal

anti-patterning. The rotation speed

of the traversing gear can be finely

controlled. The independent, motor-

powered drive of the traversing gear

also reduces the load on the winding

cylinder drive.

The rotation speed of the winding

cylinder shaft is picked up by a mo-

tion sensor (initiator). The necessary

rotation speed for the motor is calcu-

lated by the controller and transmit-

ted to the inverter. The motor speed

at power take-off is then checked

and regulated. Thus processed, these

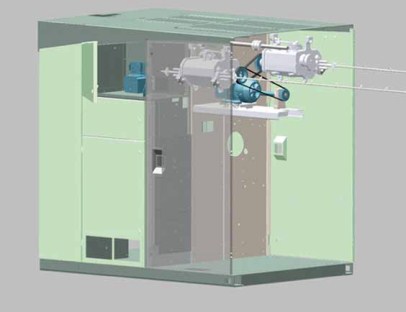

Frequency-controlled and motor-

driven, the anti-patterning control

(APC) upgrade package for rotor

spinning machines optimizes pack-

age build. The conversion kit is

available for R 1, R 20 and R 40

(version 1 to 3) rotor spinning ma-

chines.

Higher draw-off speeds in weav-

ing and knitting make optimal pack-

age build increasingly important.

Preventing pattern winding results

in improved take-off behavior in

downstream processing. Electronic

anti-patterning such as that in use

since the R 40 rotor spin-

ning machine (version 4)

has demonstrated its out-

standing qualities in the

field. Customers with R

1, R 20 and R 40 (version

1 to 3) rotor spinning ma-

chines can now also ben-

efit from this innovation.

The APC upgrade pack-

age has been developed

for this purpose. The me-

chanical regulating wheel

has been replaced here by

a frequency-controlled,

motor-powered anti-pat-

terning.

In addition to the me-

chanical

regulating

wheel, the other parts

susceptible to wear such