Basic HTML Version

The Textile Magazine

JUly 2012

|

91

The recently commissioned Brückner coat-

ing line for tufting carpets is one of the biggest

of its kind with a total length of 170 m. The

production capacity extends to a maximum of

20 million m² per year depending on the type

of fabric and the process. With this line proc-

esses like pre-spread coating for pile integration,

secondary-back laminating with flat fabric or

nonwovens and foam coating with flat foam or

embossed foam are possible.

The drying process takes place in 23 DUO-

THERM drying zones in total. This dryer type

proved to be excellent for coating in the field of

carpets. The gas-heated dryer is operated with a

temperature splitting for the thermal treatment of

the pile and the coating side. This ensures a high

drying capacity with an operation mode which is

very gentle for the pile.

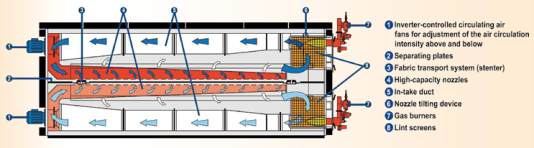

Photo 2 shows a cross-section of the DUO-

THERM dryer. The separated air circulation of

upper and lower air allows temperature differ-

ences of up to 60°C. With the Venturi mixing

system for gas heating a perfect temperature

distribution is achieved. The use of inverter-

controlled circulating air fan motors allows a fast

reaction on different types of fabric. This pre-

vents pile deformations. The central Siemens S7

control system ensures a perfect reproducibility

of the production data.

The different coatings are applied as foamed

latex mixtures. For this purpose the newly devel-

oped Brückner carpet application unit is used.

Screen 3 shows a view with foam supply, side

dams (with motorized control via edge sensors)

and motorized traversing paste distribution. The

chromium plated squeegee is water-cooled to

prevent adhesion of the latex.

The motorized nip adjustment via spindles is

made on both sides and is monitored by angle en-

coders. Normally a parallel adjustment is made,

and also corrections on both sides are possible.

The squeegee can be decharged pneumatically

via a fourfold joint. Due to the rotation around

the joint, the squeegee roller gives way not only

Dinarsu Imalat ve Ticaret T.A.Ş. established in 1955 in Istanbul for production

of yarn and blankets, began producing tufting carpets and nonwoven carpets. It

turns out high-quality products to remain competitive in the international market.

In the selection of machines and technologies the group concentrates exclusively

on European or American peak technology beginning with the tufting machine via

advanced Chromojet printing lines until coating and finishing lines.

global news