Basic HTML Version

The Textile Magazine

JUly 2012

|

39

types and material and covers the

complete yarn count range with only

one sensing head.

Even fancy yarns are cleared effi-

ciently and without compromise us-

ing simple clearer settings. Thanks

to optimized yarn path of the Zenit

sensing head, there are very few

abrasive effects on the yarn even

when the winding speed is high. The

7-segment display which is built

into the sensing head informs of oc-

currences already at the spindle.

So far, the YarnMaster Zenit F

has ensured foreign matter clear-

ing with high precision. The latest

developments have been integrated

in software and hardware develop-

ment and have again significantly

improved clearing efficiency.

Polypropylene recognition

Yarn contamination by white or

transparent polypropylene fibres

causes production and quality losses.

White PP only becomes visible after

dyeing or bleaching. Clearing im-

proves the yarn quality considerably

and prevents complaints concerning

the dyed end product. PP

and other synthetic foreign

matter that is transparent or

identical in color with cot-

ton can hardly be recognized

with conventional clearing.

To overcome these prob-

lems, Loepfe has upgraded

to the latest technology and

developed the proven P sen-

sor to the P2 sensor. Cotton

yarns as well as blends are

thus efficiently cleared.

The efficient and reliable new P2

sensor from Loepfe is customer-ori-

ented and its advantages are:

l

Controlled, reliable clearing of

synthetic foreign matter provides a

decisive competitive advantage and,

in most cases, is mandatory in mod-

ern yarn trading.

l

Complaints because of foreign

matter in the finished, dyed fabric

are reduced.

l

The door to the most demanding

market segment is opened. In this

segment, yarn cleared of polypro-

pylene is a basic pre-

requisite.

l

Better quality of the

end product and thus

better prices

l

Less raw material

waste

l

Better utilization of

resources

l

Increase in effi-

ciency of downstream

processes and cor-

responding cost sav-

ings.

Spinning

mills

processing their yarns with the

YarnMaster ZENIT FP yarn clearer

are well prepared for the future.

w

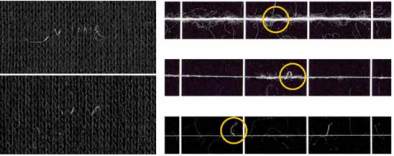

Costly polypropylene fault in the dyed end product

ITMA Asia + CITME 2012