86

|

THE TEXTILE MAGAZINE

AUGUST 2011

WLQXRXV PRGH &2

2

emissions can be

reduced by nearly two-thirds in com-

parison to exhaust dyeing processes

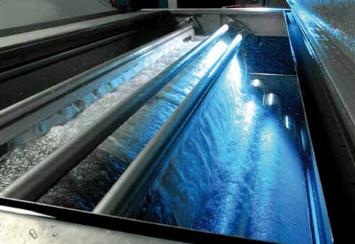

(liquor ratio of 1:7). Benninger’s

7ULNRÁH[ EOHDFKLQJ DQG ZDVKLQJ

plants and the Benninger Küsters dye

pad suit this type of application per-

fectly.

:LWK WKH &3% G\HLQJ SURFHVV WKH

UHDFWLYH G\H LV À[HG DW URRP WHPSHUD-

WXUH 7KDQNV WR PRGHUQ &3% G\HLQJ

centres with controlled dyeing condi-

tions and the developments in terms

of the dyes themselves, this method

IRU FHOOXORVH ÀEUHV IRU ZRYHQ IDEULFV

and knitwear can be used without re-

striction anywhere in the world. Sav-

ings are made not only because the

dye is set at room temperature, but

also because the intermediate drying

process after the dye application on a

KRWÁXH LV HOLPLQDWHG

7KH KHDUW RI D &3% G\HLQJ VWDWLRQ

is the padder. The Benninger Küsters

dye pad is the only dyeing padder in

the world which features the original

S-Roll technology. This allows to run

SURGXFW VSHFLÀF FRUUHFWLRQ SURÀOHV

for the dye application. As a result,

this technique therefore not only sets

the benchmark from an environmen-

tal and commercial point of view, but

also in terms of quality.

Benninger will show at ITMA a

FRPSOHWH &3% G\HLQJ FHQWHU 6SHFLDO

highlights such as dyeing with only 2 l

dye liquor during nip dyeing and just

in time dyestuff solution preparation

improve the process reproducibil-

ity and reliability, but reduce another

time the consumption of dyes and

chemicals.

Another ITMA highlight is Ben-

ninger’s new remote management

information system which is suitable

for all types of smartphones and table

3&V ,PSRUWDQW PDFKLQH DQG UHFLSH

ÀJXUHV ZLOO EH DYDLODEOH DW DQ\ WLPH

and any place. Besides production

data and machine status information,

PDFKLQH HIÀFLHQF\ DQG PDLQWHQDQFH

status, the actual consumption data

will also be judged and graphically

shown as carbon footprint.

7H[WLOH SURGXFWV ZKLFK DUH ÀQLVKHG

on Benninger systems have an ex-

cellent impact on the environment.

What particularly stands out is the

low water consumption of the Ben-

QLQJHU ÀQLVKLQJ PDFKLQHV IRU NQLW-

wear and woven fabrics. Besides, of

importance is the recycling of water

and energy from Benninger plants,

with the aid of which it is now pos-

VLEOH WR UHÀQH WH[WLOH V\VWHPV WR WKH

stage where the discharge of waste

water is reduced to zero.

ItMA 2011

– preview