Draft Air is a key component provider to the textile sector. It provides complete humidification and centralised waste recovery solutions to the textile industry on a turnkey basis.

Draft Air is a key component provider to the textile sector. It provides complete humidification and centralised waste recovery solutions to the textile industry on a turnkey basis.

With minimal investment and workforce, Draft Air commenced its journey in 1986 under the able guidance of Mr. G.D. Panchal, its Founder and Chairman. Today, Draft-Air’s state-of-the-art humidification, ventilation, pressurisation, waste recovery, and dust extraction & air conditioning systems have met with success at every turn as they expand markets across industries and geographically.

The company philosophy of treating each client, his requirements and conditions as separate and unique, and to design from scratch for each such set of parameters, as opposed to standardised solutions, has paid rich dividends. Creative design, incorporating innovative concepts, sophisticated equipment and processes worldwide, coupled with a passion for delivering only the very best, sticking to pre-determined schedules and continued after-sales monitoring and upgradation back-up, has been the hallmark of the company’s commitment.

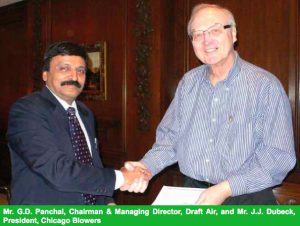

Draft-Air’s recent collaboration with Chicago Blowers, an American partner, marks a milestone in its career. This collaboration enables it to stretch its reach beyond the borders of the textile vertical.

Draft-Air’s recent collaboration with Chicago Blowers, an American partner, marks a milestone in its career. This collaboration enables it to stretch its reach beyond the borders of the textile vertical.

“The joint venture with Chicago Blowers Corp (CBC) is more of a technical collaboration where we would be manufacturing products using their technology”, said Mr. Prakash Panchal, Joint Managing Director.

CBC, a manufacturer of different types of fans and blowers, was established in 1947 in Chicago. The company moved to its current manufacturing facility at Glendale Heights in 1968 and since then has expanded and modernized the plant a number of times to provide the best technology to the customers.

CBC was the first fan company in the world to design and sell a centrifugal fan blade (1958) with an airfoil shape in the commercial market. This new shape meant that the company fans could produce the same airflow requirements as its competitors but with 20 per cent less energy.

Today CBC products are used for various applications such as heating, ventilating, pollution control and air-conditioning in areas like helicopters, locomotives, hospitals, steel mills, power plants, sugar mills, paper mills, glass industry, cement plants and processing plants. The fans are approved by the American Petroleum Institute (API).

CBC fans are in operation at the Sydney Opera House in Australia, the Petronas Twin Towers in Malaysia, the Pentagon, on the elevated tracks in Chicago, McCormick Place and the United Airlines terminal at O’Hare.

The collaboration with the company enables Draft-Air to produce fans ranging from 0.5 hp to 5000 hp according to customer demand. The company is now expanding into another unit to manufacture fans for various industries. The new facility will house all the modern processes and technology available in the market to produce fans of superior quality.

Draft-Air has also upgraded its existing manufacturing facility with latest CNC machines imported from Europe to improve the quality and production capacity.

The company range of products covers textile air engineering (humidification systems, refrigeration systems, automatic control system, fibre recovery plants and yarn conditioning); ventilation and air pressurisation system (power plants, steel plants, cement industries, refineries, bulk drugs and pharmaceuticals, electronics manufacturing units, mines and tunnels, workshop buildings, and cinema/community halls); special-purpose fans for power plants, metallurgical industries, boiler industries, refineries, radiators and heat exchangers, process industries, cement plants, petrochemicals and fertiliser industries.

Draft-Air recently bagged and commissioned some prestigious projects such as KPR Mills’ 1,00,000 spindle spinning project, Garg Acrlylic 64,000-spindle spinning project, Arvind Ltd. 112 looms, Winsome Textiles’ 40,000-spindle spinning project, Gimatex spinning & weaving project, AMW – Asia’s largest truck assembly line, BHEL Ukai – 500 MW thermal power plant, BHEL Hazira – 225 MW CCP plant, and BHEL Sikka – 500 MW thermal power plant.

Draft-Air recently bagged and commissioned some prestigious projects such as KPR Mills’ 1,00,000 spindle spinning project, Garg Acrlylic 64,000-spindle spinning project, Arvind Ltd. 112 looms, Winsome Textiles’ 40,000-spindle spinning project, Gimatex spinning & weaving project, AMW – Asia’s largest truck assembly line, BHEL Ukai – 500 MW thermal power plant, BHEL Hazira – 225 MW CCP plant, and BHEL Sikka – 500 MW thermal power plant.

The Indian industrial fans is a Rs. 1,000-crore industry. Draft-Air is gearing up to enhance its market share. It also plans to cater to the needs of customers from the Middle-East, Pakistan, South Asian and African countries.

As part of value addition for its clients, the company also provides consultancy on design of air engineering systems during the initial phase of projects with a view to minimizing the construction cost as well as the power requirements with ease of operation and maintenance.

Even after diversifying into various fields, the company considers textile vertical as its primary business sector, generating nearly 60 per cent of its revenues last year from it.

The company spokesperson, Mr. Prakash Panchal (JMD) says that Draft-Air will be looking at an aggressive approach in the near future to increase its volumes and market share domestically in the textile industry. The company has set ambitious targets for 2012 and with their recent JV signed, their team is all confident in reaching them.

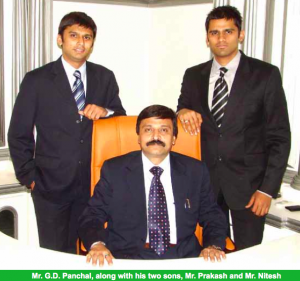

Draft-Air’s Founder and Chairman, Mr. G.D. Panchal, along with his two sons, Prakash and Nitesh, are supported by an excellent team of highly qualified, experienced and talented professionals and the most up-to-date computer assisted system design whose synergetic insights can ensure that Draft-Air remains at par to the best in terms of quality offered globally.