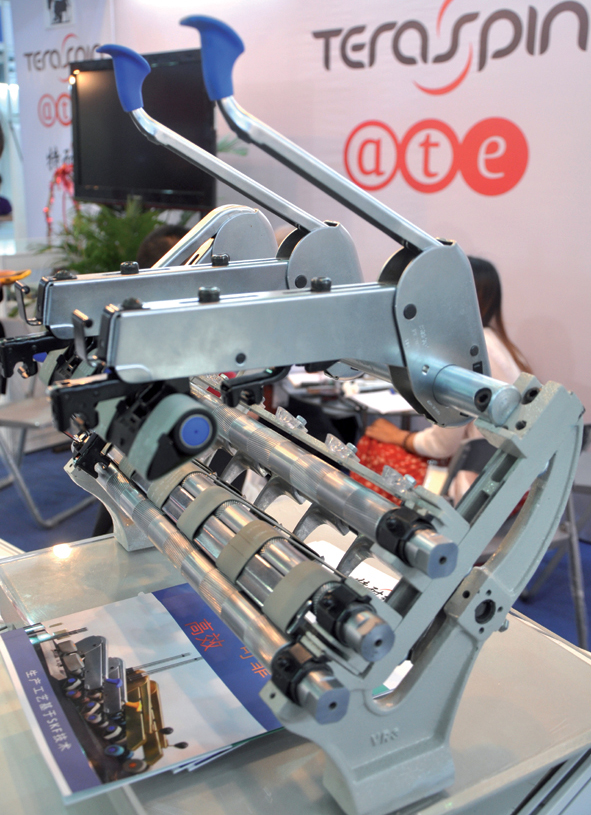

A.T.E. has launched its new brand TeraSpin for spinning textile machinery components that have come within its fold with the acquisition of SKF India’s textile machinery components business. The product range covers high-speed spindles, drafting systems and top rollers for ring frames and speed frames.

A.T.E. has launched its new brand TeraSpin for spinning textile machinery components that have come within its fold with the acquisition of SKF India’s textile machinery components business. The product range covers high-speed spindles, drafting systems and top rollers for ring frames and speed frames.

It all began a couple of years ago when A.T.E. learnt that SKF India was seeking divestment of its textile machinery components operation. There could not have been a better opportunity for A.T.E. which was looking forward to furthering its manufacturing business in textile engineering, to serve domestic as well as international markets. The subsequent agreement reached between SKF India and A.T.E. led to the acquisition of SKF India’s textile components business by A.T.E.

It all began a couple of years ago when A.T.E. learnt that SKF India was seeking divestment of its textile machinery components operation. There could not have been a better opportunity for A.T.E. which was looking forward to furthering its manufacturing business in textile engineering, to serve domestic as well as international markets. The subsequent agreement reached between SKF India and A.T.E. led to the acquisition of SKF India’s textile components business by A.T.E.

This was considered a perfect fit on all accounts as the years of legacy built by SKF is being passed on to a committed player in the Indian textile engineering field with over 70 years of experience and keen to nurture and further develop the business.

The acquisition is now complete, and SKF has also fully transferred the technology used for manufacturing these components to TeraSpin. TeraSpin will thus manufacture these components based on SKF technology, ensuring high product performance and durability.

The acquisition is now complete, and SKF has also fully transferred the technology used for manufacturing these components to TeraSpin. TeraSpin will thus manufacture these components based on SKF technology, ensuring high product performance and durability.

TeraSpin is building a new state-of-the-art manufacturing facility in Ahmedabad, which is nearing completion. The manufacturing operation from SKF, Pune, is being shifted to this new factory, and TeraSpin will soon begin its full-fedged operations. To ensure uninterrupted supply of products to its existing customers in the intervening period, TeraSpin has already built enough stock at its Coimbatore depot.

TeraSpin is fast establishing itself both in India and international markets. It has received overwhelming interest from its domestic customers that include leading OEMs and textile mills. Also, in the very first month of its launch, TeraSpin products were exported to Germany, Indonesia and Bangladesh, while the team is working to penetrate Thai, Turkish and Taiwanese markets as well.

The company has also been participating in all the major textile shows like that in Bangladesh, Indonesia and ITMA Asia held recently in Shanghai. A.T.E. is looking to enter the Chinese market for its TeraSpin brand, and the response has been very positive, says Mr. Laxmikant Rathi, Business Head – Spinning Accessories, Exports & Ginning.

“China is a very competitive and challenging market, but we are confident of establishing a strong presence for our brand. We are in touch with all major OEMs and the response has been very encouraging”, adds Mr. Rathi.

“China is a very competitive and challenging market, but we are confident of establishing a strong presence for our brand. We are in touch with all major OEMs and the response has been very encouraging”, adds Mr. Rathi.

Typically, spinning machinery components are offered by the European manufacturers which are high on quality and price. The Chinese components are known to be low on price and performance as well. TeraSpin is positioned to offer European quality at competitive price.

The TeraSpin factory epitomizes A.T.E.’s thrust on energy and water conservation. The factory is being built at Sari, 30 km from Ahmedabad, on the Ahmedabad-Rajkot highway. It will encapsulate various green building technologies and features, and will seek LEED (Leadership in Energy and Environmental Design) certification, which is a green building rating system.

The green features will make the building energy and water efficient, prevent environmental pollution and also make the indoor air quality healthy for its occupants.

To reduce energy consumption for cooling, technologies like HMX-Ambiators from HMX Systems, an A.T.E. group company, an energy efficient and healthy cooling solution, a special insulation material in the roofing, and a new concept of structural cooling will be used. The carbonate sheets provided in the factory roofing and window glasses and the LED bulbs for the street lights will reduce energy consumption for lighting.

These measures, together with photovoltaic panels and a solar dish, will make the building highly energy effcient. Besides, an effective energy monitoring system will be installed for all major equipment and energy usage areas to achieve reduction in energy consumption per unit of production on a continuous basis.

These measures, together with photovoltaic panels and a solar dish, will make the building highly energy effcient. Besides, an effective energy monitoring system will be installed for all major equipment and energy usage areas to achieve reduction in energy consumption per unit of production on a continuous basis.

For water conservation, TeraSpin will have rain water harvesting and will also utilize a reverse bore well which will recharge underground water in monsoon.

For environmental protection, 3-mm thick PU flooring designed specially to prevent soil contamination in production areas will be used. The factory is being painted with low volatile organic compound (VOC) paints to minimize environmental contamination. Also, TeraSpin is planning to reduce, re-use and recycle factory waste to the extent possible.

All in all, TeraSpin hopes to make its mark in terms of its commitment to both the textile industry and the environment.